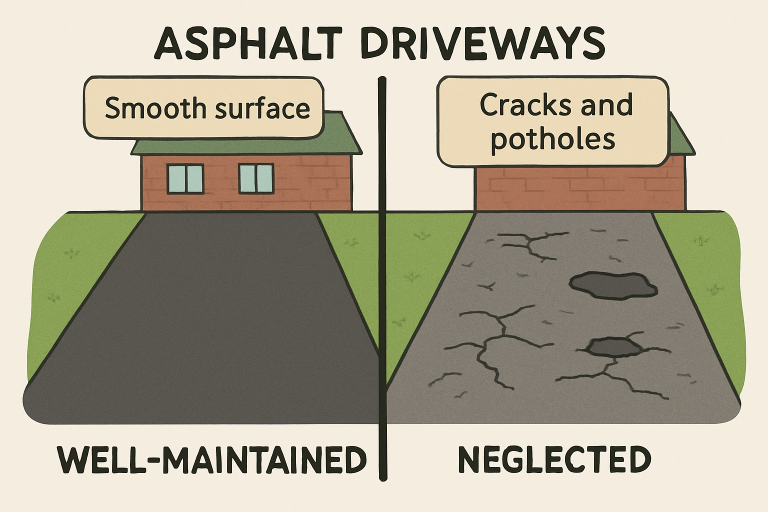

Regular asphalt maintenance is essential for preserving the longevity and functionality of paved surfaces. Over time, exposure to sunlight, moisture, and heavy traffic can cause cracks, potholes, and surface wear, compromising the structural integrity of the pavement. Routine upkeep, including sealcoating, crack filling, and timely repairs, helps prevent minor issues from escalating into costly damage, ensuring that roads, driveways, and parking areas remain safe and durable for daily use. By addressing early signs of wear, property owners can significantly extend the lifespan of their asphalt surfaces while maintaining smooth, even pavement that supports both vehicles and foot traffic.

For businesses and property managers, consistent maintenance practices also play a crucial role in overall operational efficiency. Services such as parking lot paving La Porte IN emphasize proactive care, which not only protects the pavement but also reduces long-term repair expenses. Additionally, well-maintained surfaces enhance usability and appearance, thereby contributing to a safe and visually appealing environment for both drivers and pedestrians.

Importance of Regular Maintenance

Being proactive with maintenance means addressing vulnerabilities before they escalate into major repairs or replacements. Asphalt surfaces are exposed daily to damaging ultraviolet rays, water infiltration, fluctuating temperatures, oil spills, and heavy vehicle traffic. Left unchecked, even small cracks from these exposures will widen and deepen, forming potholes and contributing to structural weaknesses.

Early intervention—such as quickly sealing cracks—prevents moisture from seeping into underlying layers, which can otherwise cause the foundation to erode over time. Preserving the integrity of pavement with timely repairs is one of the most effective ways to maintain both function and aesthetics.

Common Maintenance Practices

There are several standard practices that, when used consistently, extend the performance and appearance of asphalt surfaces:

- Sealcoating: Applying a fresh protective coat shields pavement from harsh UV light, rain, and surface chemicals, keeping the surface flexible and less prone to brittleness and cracks.

- Crack Sealing: Filling cracks as soon as they appear stops water and debris from compromising the base layer and causing long-term structural damage.

- Pothole Repair: Prompt filling of any potholes helps restore a smooth surface and prevents additional moisture from entering the base, which would otherwise lead to more extensive erosion.

- Surface Cleaning: Regular removal of dirt, leaves, and oils deters chemical breakdown and weeds, both of which can be surprisingly damaging to pavement if allowed to accumulate.

Benefits of Preventive Maintenance

- Extended Pavement Life: Studies by the Federal Highway Administration have shown that planned maintenance can add 5 to 10 years to the life of pavement surfaces, greatly reducing the frequency of major reconstructions.

- Enhanced Safety: Smooth, well-maintained pavement minimizes trip hazards and reduces tire damage, thereby lowering the risk of accidents for both pedestrians and vehicles.

- Improved Aesthetics: Clean, even pavement presents a positive image for businesses or residences, influencing curb appeal and property value.

Cost-Effectiveness of Maintenance

While it may be tempting to defer maintenance to lower short-term costs, this strategy typically results in higher long-term expenses. Minor, inexpensive interventions—such as sealcoating every two to three years—help guard against oxidation and water infiltration, which are the precursors to significant failure. Major reconstruction or replacement, by comparison, can be 10 times more expensive than routine preservation treatments. Engaging in preventive maintenance is one of the most cost-efficient ways to maximize asphalt investment.

Environmental Impact

Regular asphalt maintenance benefits not only property owners but also the environment. By extending the life of paved surfaces, maintenance reduces the need for new raw materials and major construction activities that produce waste and emissions. Preventive practices, such as crack sealing and patching, decrease the volume of asphalt debris sent to landfills and lower the carbon footprint associated with manufacturing and transporting fresh asphalt mixes. Sustainable maintenance is gaining emphasis as infrastructure ages, and resources are more closely managed.

Best Practices for Maintenance Scheduling

- Regular Inspections: Schedule inspections at least twice a year, and after major storms, to identify new cracks, surface wear, or debris buildup.

- Timely Interventions: Address any issues found during inspections promptly, as rapid intervention prevents escalation into more expensive problems.

- Professional Services: Collaborate with certified and experienced professionals for sealcoating, crack filling, and repairs, ensuring each task is performed to industry standards and using the right materials.

Adjusting the timing and scope of maintenance tasks to local climate and usage patterns will further optimize performance and lifecycle outcomes.

Conclusion

Ongoing asphalt maintenance is essential for extending pavement life, ensuring user safety, and controlling costs. Property owners who invest in preventive care—such as sealcoating, crack filling, and prompt pothole repair—preserve their investment, reduce long-term expenses, and contribute to a more sustainable built environment. By partnering with trusted professionals and adhering to a strategic maintenance schedule, pavements can remain smooth, attractive, and functional for many years to come.